It is important to extensively Test the accompanying specialized materials, operation manuals, upkeep manuals, attachment instructions, Laptop computer software and directions and retain them appropriately, as failure to do so could avoid the equipment Device from accessing further features and make routine maintenance tough.

For the reason that CNC machining can Slice a higher selection of totally dense, tough resources like aluminum 5052 and stainless steel, it truly is perfect for developing fixtures or molds.

CNC device instruments have increased precision than regular machine tools. Over the machining process, the automated machining manner of CNC device equipment can prevent errors caused by human things, leading to fantastic dimensional consistency, superior precision, and really secure machining top quality for a similar batch of parts.

Thirdly, the operator needs to be proficient in software enhancing, and compensating for parameters in Each and every process as well as diameter and duration of your cutter or grinding wheel.

Clever producing is a different production mode that combines new-era data and communication technology with Sophisticated production technology.

One trade-off when Benefiting from the significant efficiency of CNC machining processes is usually that geometric complexity comes at a cost. Simple, chunky parts are the most effective designs for CNC milling and turning.

Ahead of replacing the spare board, Test the related circuits to stop detrimental The nice board resulting from a brief circuit.

The earliest machined object ever found out was a bowl found in Italy and manufactured in seven-hundred B.C. using a lathe.

When picking a CNC machine Instrument, it’s necessary to personalize the choice according to The shopper’s requirements. For that reason, the precise price must be talked over and verified Together with the manufacturer from the CNC machine Device.

It is important to note that some faults is usually right confirmed based on the fault prompt and manual, but for Other individuals, the particular explanation for the fault may differ in the prompt or a Discover number of faults may well induce a single symptom.

Have you at any time wondered how CNC machines condition our world? These functional equipment revolutionize manufacturing, dealing with tasks from very simple drilling to advanced milling. In the following paragraphs, we’ll investigate the varied…

Which milling system features greater final results for CNC machining: climb milling or typical milling? This article dives to the pros and cons of each system, detailing how the route of…

That is a batch-primarily based process that tumbles vibrating media to eliminate sharp edges and burrs on CNC parts. Tumbling can clear away machine marks on exterior surfaces. Parts around 8” might need a manual critique.

From the Uncooked supplies costs, structural parts have the very best proportion, accounting for forty%, as well as their charges are greatly motivated by steel.

Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Andrew Keegan Then & Now!

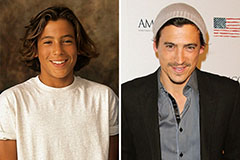

Andrew Keegan Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now!